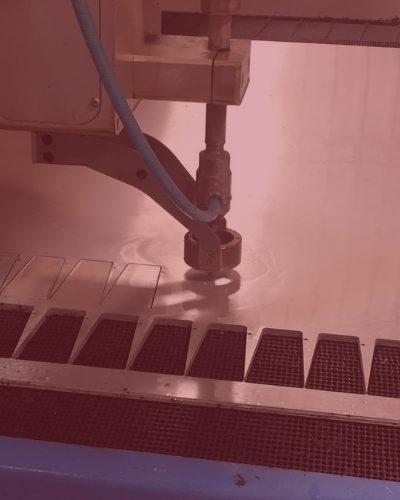

AJL Machine manufactures high quality waterjet parts for customers all over the United States. Waterjet cutting is the most versatile manufacturing process for cutting high tolerance (+-.005″) complex shapes. The technology pushes a 60,000-psi stream of water through the nozzle that will cut through an 8″ steel plate. Abrasive sand is mixed in with the high-pressure water streams at various speeds to cut through the strongest materials. The process allows us to create intricate parts with a smooth edge. Waterjet cutting can cut materials ranging from Stainless Steel, Steel, Aluminum, Plastics, Wood, Rubber, and Foam along with many others. With a table size of 6 feet by 12 feet tall, all standard sheet stock materials are possible. AJL Machine has 2 Waterjet machines and the capacity to produce millions of production parts per year. Ideal part volumes are 1,000 to 1 million parts. Our On-Demand manufacturing process and the speed of the Waterjet machines allows us to produce thousands of parts per day and eliminates the need for our customers to carry inventory with lead times from 3 days to 4 weeks, depending on volume. AJL Machine has 5 degreed engineers in house to provide the best nesting and stacking of materials to maximize the efficiency of the machine output, resulting in cost and time savings for our customers.

We offer custom Waterjet Manufacturing for a variety of clients in a broad range of industries, including:

- Consumer Goods

- Packaging

- Pharmaceutical

- Aerospace

- Marine

- Agriculture

Tolerances: +-.005″

Table Size: 6′ Wide x 12′ Long

Desired File Type: .DXF

Kerf: 0.03″ – 0.04″

Material: AJL offers many available materials on the shelf, and can bring in nearly any available sheet stock material from our vendors ranging from 48″ x 96″ to 72″ x 144.”

Applications:

- All metal parts, including carbon steel, stainless steel, aluminum

- Plastic parts for wood panels, including MDF, Hardwoods, Veneer

- Jigs and fixtures for manufacturing assembly

- Signage substrates and framework

- Pressure sensitive Adhesives that are pre-applied to substrates

- Ability to alter design to fit production needs

- Contact us for your specific application need

Materials:

- Plastic

- Aluminum

- Stainless Steel

- Carbon Steel

- Composites

- Acrylic – Machine edge polishing services available

- ABS

- Polyethylene

- Polypropylene

- Rubber

- Fabrics

- Contact us for your specific material need